Hot water shrink tank is mainly used for the heat shrink function of bulk pork and beef after packaging, especially is used on packing after vacuum packing. It is also called hot water shrink machine or hot shrink machine, or hot dip shrink machine, water dip shrink machine, lift type hot water shrink machine, heat shrink machine and so on, is a semi-automatic hot water shrink device, used for packaging and processing frozen meat, fresh meat products mainly.

The shrinkable film is used to wrap the meat product or other package. After heating, the shrinkable film will shrink and wrap the product fully to show the appearance of the product, improve the display of the product, and increase the sense of beauty and value. It will keep meat tender and enhance the sealing strength to reduce the rate of broken bags also.

In the process of shrinkage, the quality of meat products is not affected because it use high barrier heat shrinkable bag, it can rapidly and perfectly shrink. The goods packed by this machine can be sealed fully, moisture-proof, pollution-proof, and protect the goods from external impact. After heat shrinkage, the thickness of vacuum bag is increased, and the water resistance and puncture resistance are improved. The high oxygen resistance of vacuum packaging bag improves the shelf life; especially the oxygen resistance is more significant after contraction. The shelf life of pork can reach 40 days by using this packaging method under good sanitary conditions and temperature control.

The machine adopts intelligent temperature control independent heating design, half an hour before start of work, please turn on the power switch to set the required water temperature, water will be preheated. When you work, just put the product on the platform, and then press the start button. The electric motor drives the platform to lift and dip the product in the water. When the automatic platform is raised, the operator takes out the product and loads the next batch to do next work cycle.

The machine is advanced in design, complete in function, reliable in performance, compact in structure, beautiful in appearance, stable in quality, high in efficiency, long in service life, wide in application, convenient in use and maintenance, and high in cost performance.

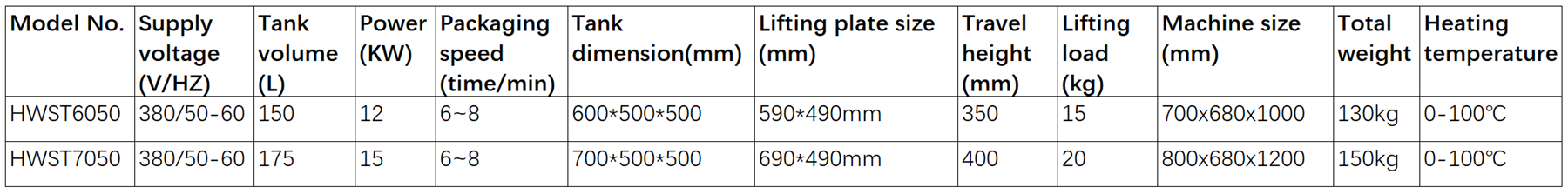

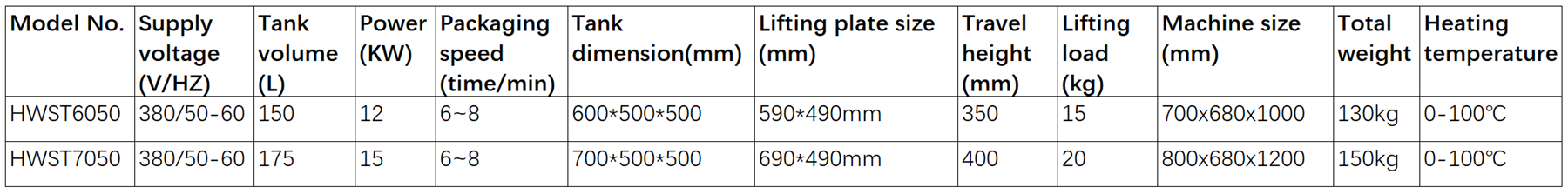

Technical specification reference (all data customized requirement acceptable):

Our machinery advantage:

1. Constructed entirely of stainless steel SUS304, simple and strong structure, suitable for the corrosive environment of food production and packaging workshop, easy to clean and maintain.

2. Electric heating temperature is adjustable; semi-automatic/automatic function switch is adjustable; support board up and down time adjustable.

3. Equipped Emergency Stop button and low water level warning.

4. Efficient electric heating and equipped high performance heat insulation board to avoid heat loss.

5. The working circuit of the equipment adopts single main circuit and multi-control design. Under the premise of ensuring safety, the stability of working circuit is greatly improved. It’s programmable temperature control or PLC control optional.

6. Simple push button cycle operations.

7. Easy fill and drain tank design.

8. There are two ways to lift: 1, electric (reducer) 2, pneumatic (cylinder)