+86 13011663939

swallowmachine@163.com

This automatic sealing and cutting machine can be used for automatic online shrinkage products packing, It has L type and side cutting and up-down sealing and cutting three types, it's a fully automatic unmanned operation sealing and cutting machine, widely used in mass production of packaging assembly line operations, high work efficiency. It suit for different sizes of products such as software, food, cosmetics, printing, pharmaceutical and ceramic and so on.

It equipped automatic products photoelectric detection system, automatic feeding or manual feeding can be selected as will. It uses the method of half-corresponding folding film andother three sides be sealed. The thermostatic heating sealing and cutting system can be used for sealing and cutting various industrial standard heat sealing films such as PE and POF. The sealing is firm and beautiful, especially suitable for POF sealing and cutting. When changing the size of the product, it only needs to be simply adjusted by hand wheel without replacing any parts, which reduces the replacement time of the product and makes it easier to operate. The front-end feeding system with adjustable speed and the back-end storage working platform make the machine run at high speed and automatically without people.

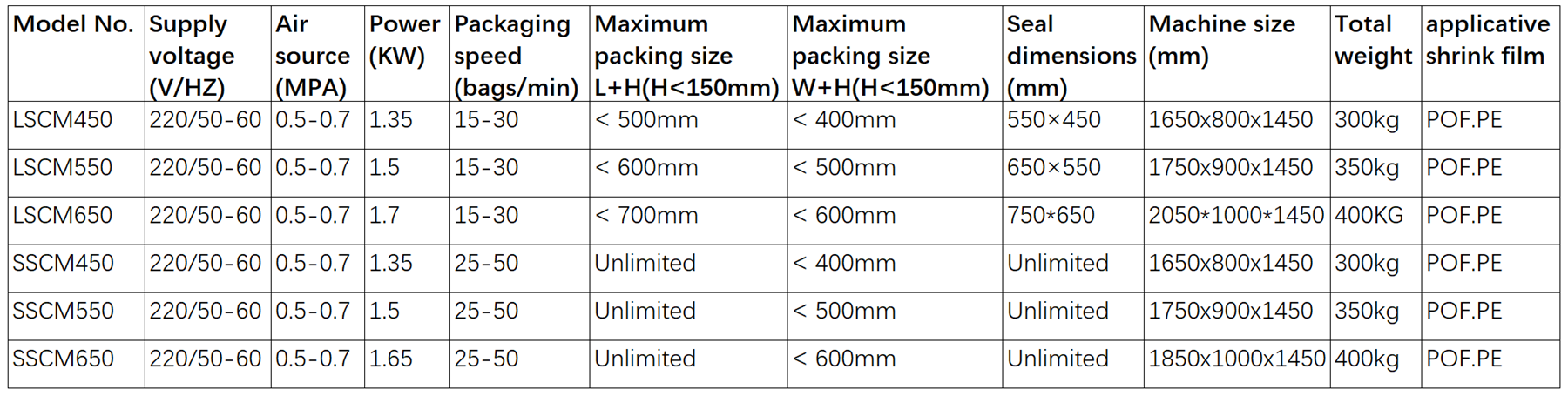

Technical specification reference:

Our machinery Features:

1, Sealing cutter use aluminums alloy with USA DuPont Teflon coating, it’s antis ticking and high temperature resistance, the sealing result will not crack, not burned, not smoke.

2, Automatic feeding, length can be automatic adjustment via combination of electric eye and timer. It equipped with an induction motor, automatic waster recovery.

3, Equipped with imported photoelectric detection, horizontal and vertical detection can be equipped each with a group, easy to switch to select. For thin and small package can be completed sealing easily.

4, Temperature controller with digital temperature controller, sealing knife temperature extremely sensitive and accurate, can be set at your option.

5, Sealing knife with self-protection function, effectively prevent the false cutting on packaging.

6, When the packing size change, the adjustment is very simple, do not need change the mold or bag.

7, The machine is equipped with the protective cover on sealing part, and with automatic alarm function, greatly improve the safety of the operator.

8, The whole set of production lines achieve the unmanned operation of the connection.

9, L type sealing and cutting machine PLC control system optional.

Sealing and cutting machine simple direction for use:

1, Travel setting The longer time means the excess part of the shrinkage film longer, you should test the finish result after contraction several times. (pay attention to the relaxation phenomenon after contraction).

Note: the time is too short, sealing and cutting knife easy to cut packaging. It need set 0.1~0.5 seconds usually, but should consider the different thickness of packing materials, time is not the same.

2, Counter

When the packaging through the electric eye switch and sealing cutting knife down and up, the number on the counter will be displayed. When you want to reset counting, just press “RESET”

3, The electric eye switch

It equip on both sides of the conveyor belt.

When the package passes through the electric eye, the travel setting device acts, and the sealing and cutting knife drops to seal and cut.

4, The selective switch

Manual position must be selected when installing the film or adjusting the machine. At this time, the conveyor belt does not run and the electric eye is closed. When start formal packaging, choose the automatic position, when the conveyor belt is running, the electric eye starts. When the packaging touches the electric eye, the sealing cutter will automatically drop. Please be careful not to touch the electric eye with your hands.

5, The sealing temperature

Usually the transverse sealing temperature is set at about 180°C and the longitudinal sealing is set at about 300°C. (Different shrinkage film material and thickness a little difference).

6, The sealing time

Usually is set at about 0.8 second. (Different shrinkage film material and thickness a little difference).

7, The maintenance

Please draws off cylinder water monthly. (There’s one white button under cylinder, the water will be out when you press). Please check the oil monthly

Phone: +86 13011663939

Add: No.4799, Shengli East Street, Weifang, Shandong, China