The Thermoforming (stretch-film) vacuum skin packaging machine is fully automatic packaging solution for vacuum skin packing of meat products, fish and seafood, cheese, ready meals etc.,

This Vacuum packing type is a new fashion packaging way at present. Our vacuum sealing machine works from film thermoforming, filling, vacuum pumping, sealing to cutting wholly.

For this single face thermoforming vacuum packing machine, the upper forming film is rigid; bottom sealing film is special skin pack film (stretch-film). Rigid trays are formed in the forming chamber and pre-designed mold after you telling us your needing. So you never need pre-made trays once you confirmed your requirement.

We use original German BUSCH or Rietschle vacuum pump, it’s widely applied to food and medical packaging industry characterized by simple, intuitive and smooth operating experience.

Vacuum degree:0.1mbar(0.01Kpa)

Compressed air: ≥0.6Mpa

Cooling water:0.15 M pa

Capacity: 200-400 cycles/h

Air supply: 0.8 M pa

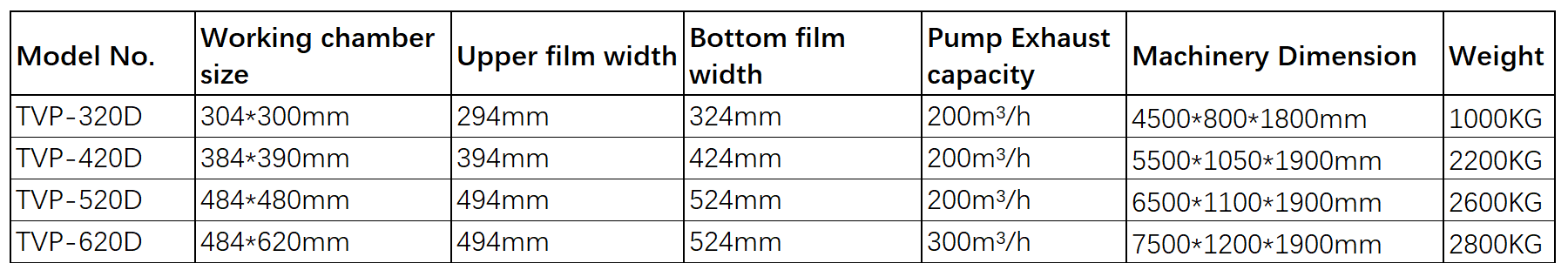

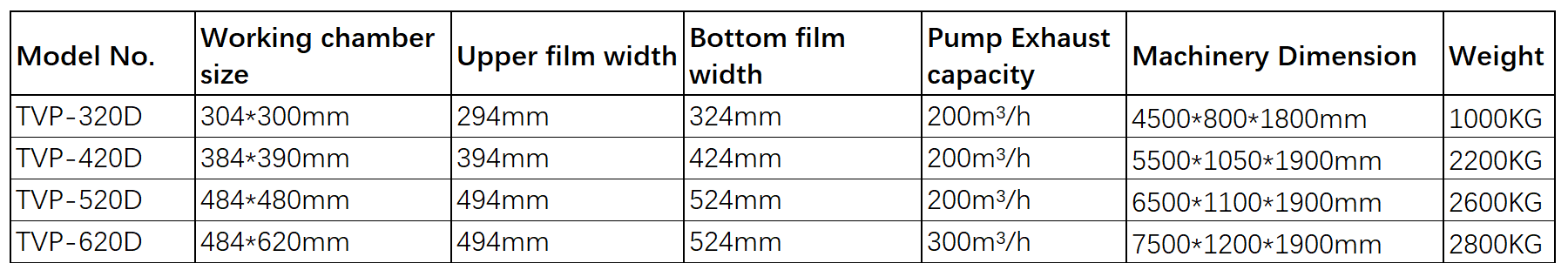

Technical specification reference (all data customized requirement acceptable):

PLC (programmable logic controller) and monitor are use German Siemens or Japan Japan MITSUBISHI or OMRON, all with 10.1 "touch human machine interface, humanized design and Simplified Chinese menu display.

Taiwanese AirTAC brand air cylinder/solenoid valve/voltage regulator. SMC or Festo pneumatic elements acceptable and more reliable performance and long service life are applied.

Taiwanese KMC or TYC transmission chains guarantee durable service.

French Schneider electrical control parts let machine performance stable and long service life. OMRON servo motor with reliable performance and ease of operation is used.

The photoelectric tracking system adopts the original imported Bonner three-color standard sensor.

Equipped with automatic DELTA code typing or spurting system; Videojet Heat transfer printer available also.

All vacuum tube, sealer and filler plate are made of silicone, AirTAC PU tube is pneumatic guarantee.

We use top international configurations for important devices always, more reliable performance and long service life are applied.

The girder made of 6061 aluminum alloy and cover 304 stainless steel, All machine made with SUS304 food grade stainless steel structure 3~5mm thickness. It improves the corrosion resistance of the equipment.

All machinery with computer remote fault handling system, fault alarm system and display, with fault alarm and fault troubleshooting analysis cause and step reset function.

All other electric parts conform to CCC certification and waterproof.

Thermoforming molds are made of aluminum alloy with durable and changeable easily with water cooling system available.

With advanced horizontal and longitudinal cutting systems, the machine’s replacement operation is more convenient. There is a scrap and waste recycling system to help maintain environmental cleanness.

All machinery pack with strong wooden/plywood case (pallet) when export and we provide video technical support or on line support or not free on-site guidance to install/debug/guide/tech etc.