+86 13011663939

swallowmachine@163.com

Continuous belt conveyor (rolling belt) vacuum packing machine used for all kinds of products, It can work on raw food, cooked food, seafood, frozen product, vegetables, dried vegetables, fruits, edible mushrooms, medicine, electronic components, clothes and other vacuum products. The machine especially suit for huge size products and suit for large scale production enterprise. The width of sealing is very big, other machines is hard to achieve. This machine is the first and best choice of big vacuum packages and high production.

This machine adopts continuous operation, fill at the front and automatic discharge at the back. It uses cam divider, accurate positioning, can be tilted at will, easy to pack soup products. The machine equipped removeable vacuum pump (external), with water cooling device for continuous and uninterrupted work. The whole machine is made of 304 stainless steel, guarantee sturdy and durable, beautiful. It has generous thickened vacuum chamber, good sealing, no deformation, and no air leakage. Rotary vane vacuum pump ensures fast pumping rate, high efficiency.

It can be used to vacuum heat sealing packaging bags, it can effectively prevent the food spoilage caused by oxidation and aerobic bacteria, to ensure quality, preservation, and color retention to facilitate prolonged storage.

Evacuate vacuum, pressure bag, sealing, cooling, waiting time can be adjusted according to your requirement. You can change the studio angle from 0° to 30° angle.

Chain driver/automatic cover/conveyor belt are continuous, guarantee production efficiency.

Equipped vacuum gauge supervise pressure.

It uses water-cooled system, so guarantee the machine can be used long time.

304 stainless steel main bodies ensure easy to clear and apply to moist environment, ensure the uniformity of packing and sealing quality.

It process flexible and rigid film all, with different thickness for several film widths, forming depth and cut-off lengths.

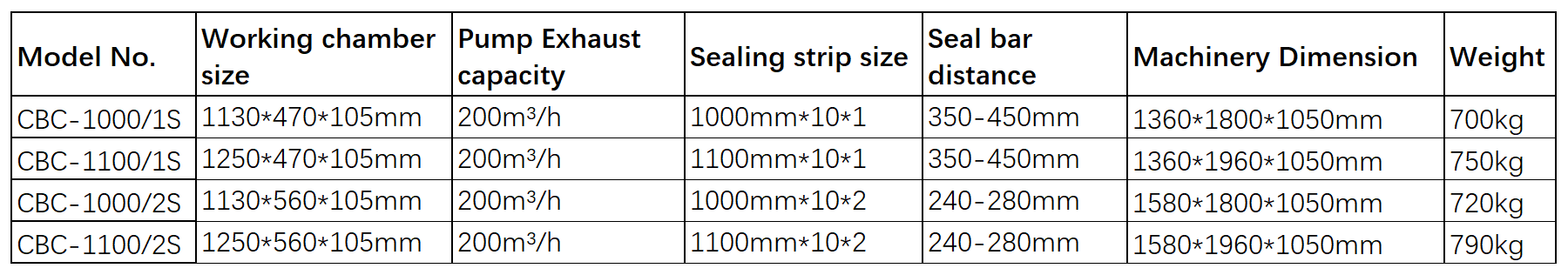

Technical specification reference (all data customized requirement acceptable):

Functional configuration features & advantage

1. Equipped four angles tiltable work table, meet various packaging requirements.

2. The side cover and the chain cover are installed separately, and the maintenance chain is very convenient.

3. The surface of the studio is more beautiful and clean.

4. The chain use a large pitch chain and the tensile strength is very good.

5. The operation panel has two kinds of computer touch screen operation panel and electronic button panel for users to choose, simple and easy to operate.

6. The strength of the discharge plate is high, the angle is very easy to adjust, and the fixing is easy.

7. Equipped well-know electricity brand, make sure the machine work well and long work life. Independent electrical box is fully sealed ensure be rinsed by clean water, easy to maintain.

8. The working room bracket use 16 mm 304 stainless steel plate production.

9. Food grade conveyor belt and belt hinge 2 mm 304 stainless steel.

10. The tow angle iron plate is used with a hook, can be well fixed on the small belt, will not fall off, and the positioning distance is large.

11. The stroke switch paddle CNC wire cutting processing, high precision.

12. The wire screws and faucets are behind; the surface of the studio is beautiful and clean.

13. Vacuum table 304 shell shockproof.

14. The studio is made of 8 mm stainless steel.

15. Equipped anti-pinch device, stable and reliable operation.

16. Frequency conversion belt, slow start, slow stop conveyor, reliable positioning.

17. Own protection for heating strip fracture.

18. Voltage can be customized.

19. Chamber depth can be customized with max deepness 130mm usually.

20. Sufficient spare parts as follows:

* Vacuum pump oil

* 20 meters hose

* Several hose connect

* Glue

* Heat strip

* Cooling water pump

* Teflon cover

* Screw driver, allen key, wrench etc.

* English manual

In a word, it’s one type easy to operate and easy to learn continuous vacuum packing machine, suit for different bag size and material automatic production.

Phone: +86 13011663939

Add: No.4799, Shengli East Street, Weifang, Shandong, China