+86 13011663939

swallowmachine@163.com

The Vertical tray sealing modified atmosphere packaging machine, in short known as MAP, which is the most popular and advanced technology in the world currently. It adopts method of modifying the composition of the internal atmosphere of a package in order to improve the shelf life. It used for the short shelf life food products such as meat, fish, poultry, and dairy because of oxygen existing mainly.

The working process similar to the vacuum packing machine, cover the trays with thermoforming film material firstly, and then exhaust the air inside the vacuum chamber, and then fill modified gas into tray, and after that seal the trays. Whole process happens in a closed chamber, the film will finally be pressed tightly on the product, same like a new skin.

The working principle is uses different functions of gases to inhibit the growth and reproduction of most microorganism and bacteria that cause of food deterioration, reducing the speed of the metabolism so as to keep food fresh and prolong shelf life. It changes the traditional practice of using various preservatives to keep food fresh. After all, preservatives contain toxic ingredients harmful to human usually. It reduces the amount of oxygen (O2) in the headspace of the package. Oxygen can be replaced with nitrogen (N2), or carbon dioxide (CO2) and so on inert gas. A stable atmosphere of gases inside the packaging can extend shelf life, such as gas flushing and compensated vacuum. It will largely help lock moisture and avoid liquid in the tray from flowing, thus to provide a longer shelf life, beautiful finishing looks and increase product quality.

It is suitable for packing both solid products like beef steak, sausage, bacon, ham, cheese and soft product, for example all kinds of seafood like sea cucumber, abalone, and fish fillet. Also it is capable of packing liquid sauce.

For Frozen product, it is freeze-proofing. The finished products after packaging is boxed type or bowl type, suitable for retail food in small packages and cold chain distribution of fresh and cooked food. The food can be eaten immediately after unpacking.

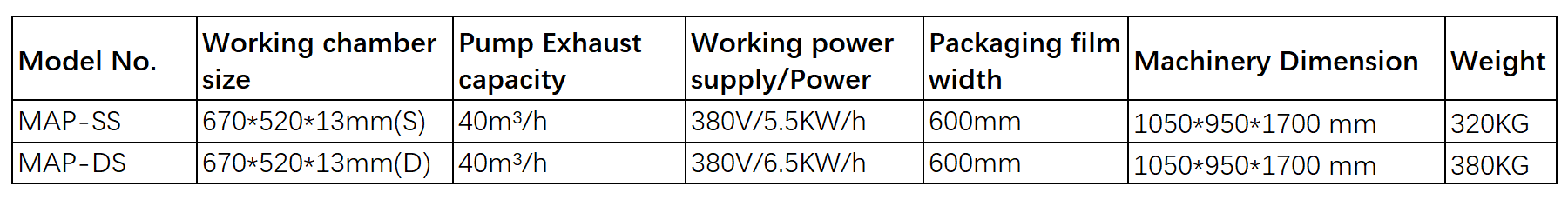

Technical specification reference (all data customized requirement acceptable):

Features

MAP Basic features are: high speed, easy operation, wide application range. It’s ideal packaging solution for various containers, including plastic trays, cups, bowls, etc. It can use vacuum packing alone with adjustable vacuum degree; or use seal packaging alone with adjustable pressure; or realize vacuum-gas-seal packaging with adjustable air filling capacity.

* Our MAP machines are ideal packing equipment for various types of food products. They are easy to integrate with metal detection, weighing, labeling system.

* Control system: Use MITSUBISHI 3GA20MT PLC or Omron or German Siemens PLC, together with MITSUBISHI touch screen, easy to set and modify operation parameters, driving by MITSUBISHI high precision positioning servo motor (or Schneider brand), ensures 100% accuracy and stability.

* Temperature control system: MITSUBISHI 4 channel temperature control module, higher precision than temperature control button system; Overheating alarm; Split type heating plate with grids, guarantees better sealing quality.

* Molds: Aluminum magnesium alloy molds, high strength, durable, corrosion proof.

* Photoelectric tracking system ensure 100% accurate in printed film sealing, automatically skip the line with empty trays, misplaced trays, enhance machine performance accurately.

* Whole machine is made of SUS304 food grade stainless steel with more strength, more stability, and no deformation.

* Safety: Equipped with emergency stop/Alarm/Open-phase protector/anti-phase protector, it can be terminated in case of abnormal condition for all ongoing work programs.

* Imported silicone grease sealing ring, guarantees better sealing quality.

* Specially designed cutting system, integrated alloy blade, longer service life, easy to change.

* Design multi molds according to trays of customers individually.

* Automatic film feeding, more sanitary.

* Machine can move easily, when you press the brake, the machine will be fixed well.

* Automatic waste film recycling system.

* Ratio of O2/N2/CO2 can be changed according to needing on touch screen.

* Sealing pressure, temperature, time and other parameters can be accurately controlled to ensure the ideal sealing effect.

* Easy for maintain and operate.

* Supporting air compressor together.

* Customize wider/deeper chamber acceptable, max tray depth can be 120mm.

* Voltage can be customized as required.

* The material of trays can be PP/PET/aluminum foil.

* It can complete packing films and boxes made of different materials, such as composite film, single film and co-extrusion film, for sealing packaging.

We suggest whole machine adopts international famous brand electrical components, reliable quality, CE standard as the design criterion, safe operation.

About filling gas

Different food needs different preservation gas composition and proportion.

There’re three types of commonly used gases in MAP packaging usually, they are CO2, O2, and N2.

CO2: Inhibit the growth of aerobic bacteria.

It is a bacteriostatic gas that inhibits the growth and reproduction of bacteria. Its characteristics are following:

(1) the best bacteriostasis was in the lag period of the bacterial reproduction curve.

(2) It is easy to dissolve in water and fat at low temperature.

(3) It has bacteriostatic effect on most aerobic bacteria, but not on anaerobes and yeasts.

(4) The minimum concentration of bacteriostasis is 30% usually.

O2: It keep fresh cell sleep but still alive.

It has three functions:

(1) Inhibiting the growth and reproduction of anaerobic bacteria;

(2) Maintain the red color of fresh pork, cattle and mutton;

(3) Maintain fresh fruits and vegetables, metabolism and aerobic respiration.

N2: Protect good tray shape under atmospheric pressure.

Inert gases, which do not react with food, are used only as filling gases for mixed gases.

How to set touch screen

* We leave different holes for gases on tray sealer. Please connect them with gas source directly. Inflow gas pressure shall be 0.6-0.8Mpa.

* User can adjust gases ratio on touch screen.

* The gas mixer will mix gases and store them in another cylinder inside machine.

* The machine will automatically fill gas once inside gas less than a certain level.

* The touch screen will alarm for insufficient gas source inflow.

* Time for vacuum/gas fill/seal can be adjusted also. If want to close some function, just set the time "0".

How to get quotation and process order

1. Tell us what size of your tray.

2. Tell us which function you need. We provide 3 types:

A. vacuum and add O2/N2/CO2 mixing filling and sealing;

B. vacuum and add nitrogen filling and sealing;

C. seal directly without vacuum or nitrogen filling.

3. Before machine production, you should send us tray samples and drawing for us design your customized mold.

4. After machine ready. You’d better send us 100pcs trays and film sample for each tray size at least, we will test and adjust machine, so that to make sure machine is under good condition and it parameter set ready set for your trays. This is important to handle before shipment.

5. We will provide full sets running videos and pictures after machine testing well. We must guarantee the machine under good condition before shipment.

Phone: +86 13011663939

Add: No.4799, Shengli East Street, Weifang, Shandong, China