This platform single chamber vacuum packing machine (stainless steel cover) use for sea food/salted meat/dry fish/pork/beef/rice/medicine/electronic components/hardware/medical instruments etc.

They are able to vacuum seal all kinds of plastic and plastic-aluminum bags almost, prolongs the shelf life and freshness of all similar products. Machinery will finish the whole process of vacuum extraction, gas flushing (optional), sealing, cooling and exhaust automatically.

All machine made with SUS304 food grade stainless steel structure with 3~5mm thickness.

We accept 380v/50Hz/3Phase or customized power source, Max sealing thickness from 0.1mm to 0.5mm.

We use Integral type circuit protection switch, Time controller computer waterproofp. All other electric parts conform to CCC certification.

Machine Cycle can be control within 3~5 times/minute.

All machinery pack with strong wooden/plywood case (pallet) when export and we provide video technical support or on line support or not free on-site guidance to install/debug/guide/operation etc.

We provide Two year core components warranty if you accept our top brand configuration.

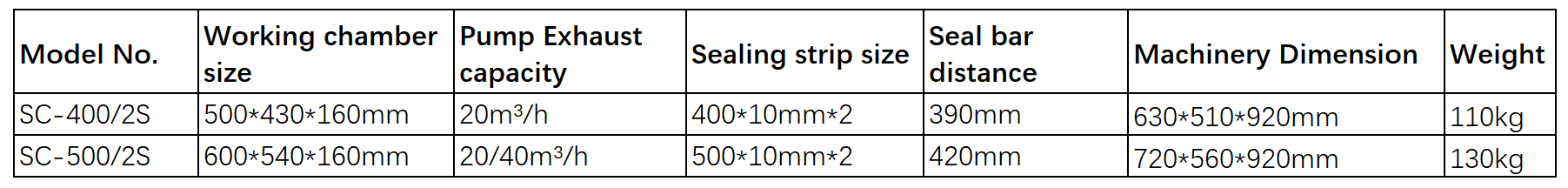

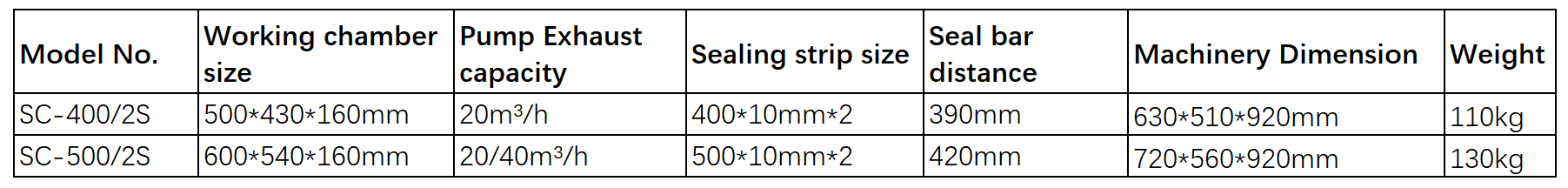

Technical specification reference (all data customized requirement acceptable):

Our machinery advantage:

1. Quality guaranteed by best structure and famous brand components.

2. Machine constructed complying to CE rules in terms of safety and hygiene.

3. Microcomputer control system & electrical box are waterproof.

4. The vacuum and package sealing is finished automatically. Parameter of sealing and vacuum can be adjusted accurately.

5. Each seal wire is controlled individually by a set of transformer, time relay, A.C. contactor, ensures temperature uniformity of heating bar; Thermal fuse is installed to protect heating bar/sealing wire, reduce maintenance cost.

6. Equipped with braking wheels for easy machine's moving.

7. Vacuum chamber cover made by stainless steel, more strong than Acrylic cover.

8. Double locking system for chamber lid support, ensure the chamber cover fasten firmly to the working plate for best quality vacuum and sealing; prevent cover deformation during the period of service life.

9. Overlap sealing function available.